We are The Engineering Resource Company

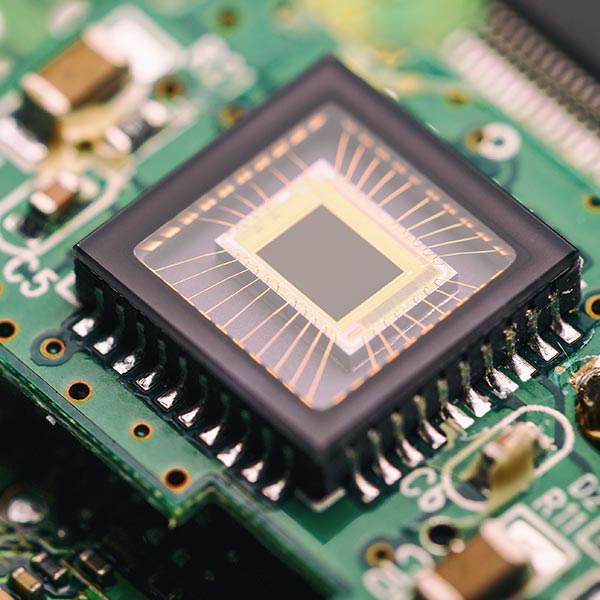

Hot Solder specialise in the development of high-reliability industrial control and data-capture solutions for a wide range of complex and highly regulated industries.

Engaging with Hot Solder

The Hot Solder team have knowledge and experience that extends across a range of highly regulated sectors such as aerospace, automotive and medical. In each engagement our project managers will work closely with your team to define the scope of the assignment. A written proposal will capture the deliverables and responsibilities and the project manager will be the key point of contact for you throughout the duration of the assignment.

We offer a comprehensive quality system designed to integrate with each of our customers’ records and processes ensuring that traceability and design history are accurately captured for the duration of the product lifetime.

At Hot Solder we understand the importance of combining design, prototyping, manufacturing and supply chain needs at every stage of product development.

Ultimately this will ensure a smooth transition from concept to production, optimisation of cost and the incorporation of reliable and repeatable technologies. In order to manage the total cost of ownership for product realisation, the team has focused services and expertise into the following areas: Design, DFx, Prototyping and Test.

Our clients come from a wide variety of business models: some clients seek to augment their own design expertise with experienced third party partners, some require feature enhancements or improvements carried out on existing products whilst they focus on new launches, others may be entrepreneurs with plans and financial backing looking for a complete turn-key product development service.

Check out our Blogs and News Articles!

For more information contact us at sales@hotsolder.co.uk

Our Services

Hot Solder has build a reputation for building first in class automation and data capture solutions for various industries such as automotive, big data, medical, aerospace, oil & gas

Our Qualities

Our Strategy

The foundational elements of the Hot Solder strategy can be summarized in three areas we believe make us stand out among our competitors:

Best value at delivering design service solutions to customers in within diverse product realisation markets

Committed to highest quality design outputs to enable customer success

Talented people passionate about innovation and customer focus

This strategy is further defined by maintaining key measures that we use to track our progress towards each area of our strategy: they are revenue to overheads ratio, project variance and customer satisfaction.